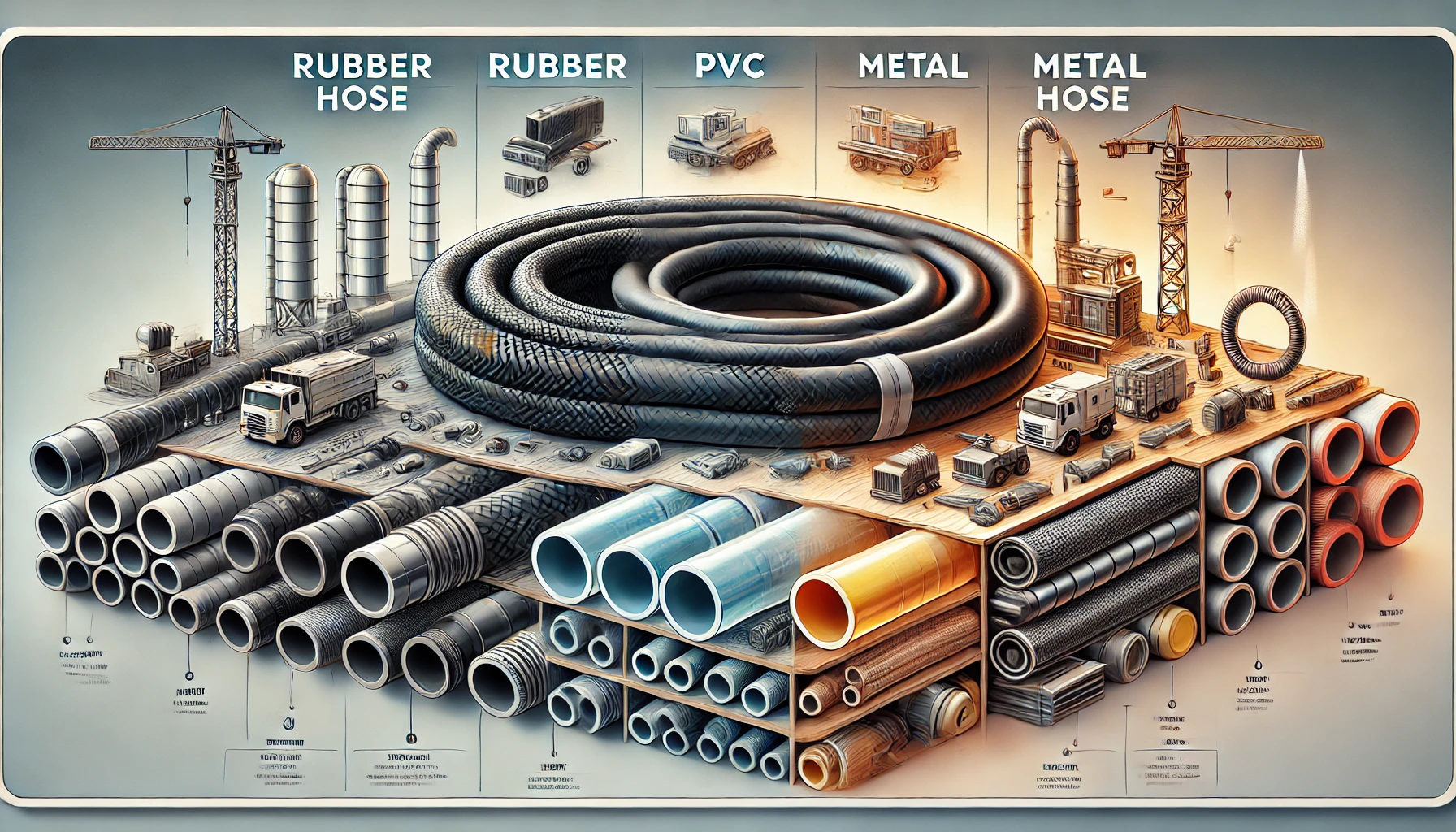

Hoses are essential parts in many sectors, as they enable the easy transfer of liquids, gases, and other substances. The choice of hose material- which can be rubber, PVC (polyvinyl chloride), or metal- affects performance, life-span, and fitness for a particular job. Therefore, all options concerning a specific requirement need to be assessed concerning the individual properties of each of the materials.

Rubber Hoses

Rubber hoses are mostly liked for their elasticity and durability. They can adapt to extreme hot and cold temperatures, making them usable in almost any region. This temperature resistance is quite helpful in industrial applications where processes may involve extreme heat or cold. Additionally, rubber hoses are sufficiently resistant to abrasion, enabling them to withstand rude treatment and contact with sharp materials with little damage. This abuse makes them great for hard applications such as mining and construction, where hoses are often treated very badly. However, these rubber hoses may be heavier than alternatives like PVC, which may make them a bit difficult to handle. Rubber hoses also tend to cost more due to their superior durability and flexibility, but this cost is often justified because of their long life and relatively trouble-free performance in rough usage environments.

PVC Hoses

PVC is one of the most commonly used materials for manufacturing hoses due to its light weight and low cost. In addition, PVC hoses have good chemical resistance which allows them to be used in many industries dealing with different chemicals and fluids. One of the downsides of PVC hoses is that they are not as flexible as rubber hoses. This inflexibility increases in cold temperatures when PVC can become rigid and brittle. For uses where the temperature can fluctuate or go low, PVC hoses become less useful. Still, they’re popular for general use due to their economical benefits and resistance to kinking and abrasion such as light-duty water discharging, gardening, and agricultural application. Improvements in technology have made these PVC hoses more flexible and resistant to wear, which increases their use in different industries.

Metal Hoses

Massive power and performing metal hoses can withstand extreme pressure and temperatures. Constructed with stainless steel, these metal hoses offer great durability making them perfect for the transportation of hot fluids, steam, or gasses of industrial use. These hoses can easily outperform and outlast rubber or PVC ones due to their essence. They are also resistant to corrosion making them highly functional in chemical plants or oil refines that have harsher environments, usually harming other, cheaper forms of hoses. Installation is one problem that comes with metal hoses, compared to the other materials, these will need more space and are not as flexible. A huge downside with these hoses is their cost. Metal hoses are expensive compared to rubber, PVC, or plastic, so budget sensitive projects will more than likely not be able to use these types of hoses. If mobility and cost-effectiveness is a key pointer in an application, metal hoses should not be used.

Comparative Insights

Looking at the pros and cons of PVC and rubber hoses, it is highly dependent on the application that will be handled. Each type of hose serves a particular purpose that benefits certain functions.

- Flexibility: If the task set is dynamic in nature, working on a high range of temperatures. It is recommended to use a rubber hose as it is highly flexible.

- Chemical Resistance: Rubber and metal hoses lack the ability to withstand harsher environments so PVC will be a better option for those looking to work with chemicals.

- Tolerance to Temperature and Pressure: Metal flexible hoses are very efficient in operating at high temperatures and high pressure making flexible metal hoses perfect for tough industrial use.

- Durability: All three materials are durable but, in order of highest to lowest durability, metal hoses are hardest to abrade and corrode, followed by rubber hoses. PVC hoses are easiest to abrade and corrode when exposed to harsh environments.

- Cost: Rubber hoses come second after PVC when it comes to cost. Construction material and manufacturing processes make metal hoses the most expensive.

Environmental Considerations

Somewhat more damage to the environment is caused by these hose materials in comparison with others. Hose made with natural rubber has less environmental impact than synthetic rubber or PVC hoses which come from petrochemical sources. However, metal hoses are very durable and are easy to recycle but their production needs high energy. There is a growing expectation that industries which participate in aims to lower carbon emission will select those materials that are environmentally friendly.

Conclusion

Choosing the right hose material ensures safety, efficiency, and durability in a number of applications. Rubber hoses are flexible and durable enough to withstand more demanding working environments while PVC hoses have an economical lightweight solution that is sufficient for general purposes. Metal hoses, on the other hand, offer durability with great strength and exceptional resistance to high pressure and temperature applications. Effective hose selection in terms of operational and environmental needs involves evaluation of the specific application in detail; such as flexibility, chemical resistance, durability, cost and impact on the environment. These considerations need to be taken whether a hose is used for industrial processes, agricultural purposes, or heavy duty operations. The right material will guarantee performance and durability as well as achieve reliability.